High-Speed Imaging & Motion Analysis for Microfluidics

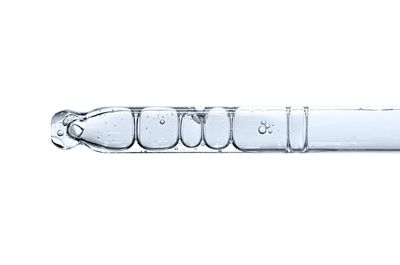

Microfluidics involves the precise manipulation of fluids within microscale channels, where fluid interactions, particle motion, and transient events occur at high speeds and within confined spaces. Capturing and analysing these phenomena requires imaging solutions with ultra-fast frame rates, high spatial resolution, and accurate motion tracking algorithms capable of resolving subtle movements in real time.

Fastec Imaging’s high-speed cameras, combined with Image Systems’ advanced motion analysis technology, provide a powerful platform for 2D tracking, velocity measurements, and dynamic event characterization in microfluidic systems. This integrated approach enables researchers to measure flow patterns, particle trajectories, and interface behaviours with sub-pixel accuracy, even under challenging lighting or noise conditions.

Key Applications:

- Cell Sorting: Track cell movement and velocity profiles within micro-channels, enhancing separation efficiency and reducing sample loss.

- Testing Controls in Microfluidic Devices: Analyse the motion of valves, actuators, and fluid interfaces through high-resolution 2D tracking, ensuring precise control and reproducibility.

- Droplet Formation: Study droplet generation, breakup, and merging dynamics using high-speed capture, providing detailed insights into surface tension effects and flow instabilities.

- Particle Characterization: Monitor particle size distribution, pathlines, and clustering behaviour with accurate motion analysis, supporting advanced diagnostics and material processing.

- Throughput Efficiencies: Evaluate system performance by analysing flow rates, mixing times, and turbulence with velocity measurement algorithms tailored to micro-scale phenomena.

- Flow Rate Measurements: Quantify acceleration, shear forces, and pressure-driven flows with real-time tracking, offering data essential for optimizing device design.

- Bubble Size and Speed Measurements: Observe gas-liquid interactions, bubble formation, and interface deformation with millisecond precision, enabling improvements in mixing and reaction kinetics.

With Fastec Imaging’s high-speed data capture and Image Systems’ robust motion analysis—including adaptive tracking, error correction, and velocity profiling—researchers can explore complex fluid dynamics with unmatched precision. This combined solution is trusted by teams across academia, medical research, biotechnology, and pharmaceuticals to accelerate discovery and improve experimental outcomes.

Material Testing and Analysis

Material testing focuses on understanding how materials deform, strain, and fail under various loading conditions. High-speed events such as impacts, crack initiation, and dynamic stress distribution require advanced imaging paired with accurate motion analysis to capture both in-plane and out-of-plane movements with precision.

Fastec Imaging’s high-speed cameras, combined with Image Systems’ motion analysis tools—including 2D tracking and 3D Digital Image Correlation (3D DIC)—provide a comprehensive solution for measuring displacement, strain, and velocity fields in real time. This integrated approach enables researchers and engineers to characterize material behavior under extreme conditions, even when rapid or complex movements occur across multiple axes.

Key Applications:

- Impact and Crash Testing: Capture rapid deformation, crack formation, and failure mechanisms during high-speed loading, improving material design and safety performance.

- Strain and Displacement Measurement: Use both 2D tracking and 3D DIC to map surface strain and out-of-plane displacement, providing accurate, markerless measurement of deformation patterns.

- Fatigue and Fracture Analysis: Monitor progressive damage under cyclic loading by analyzing displacement gradients, strain accumulation, and crack propagation over time.

- Vibration and Modal Analysis: Study dynamic responses, resonance behaviors, and natural frequencies through high-speed data capture and advanced frequency-domain analysis.

- Thermal and Pressure Effects: Observe deformation patterns under temperature or pressure variations using real-time displacement tracking in both planar and volumetric dimensions.

- Adhesion, Coating, and Joint Tests: Evaluate failure modes, bond strength, and crack initiation in layered materials by visualizing how surfaces separate and deform under load.

- Dynamic Load Profiling: Measure acceleration, velocity changes, and load-induced motions with millisecond accuracy, enabling precise modeling of stress responses.

By combining Fastec Imaging’s ultra-fast capture with Image Systems’ advanced algorithms—including adaptive 2D tracking, markerless measurement, error correction, and full 3D strain mapping—researchers gain a powerful toolset to explore material behaviors with unmatched accuracy and depth. These solutions are trusted across aerospace, defense, automotive, energy, and manufacturing sectors where understanding material integrity under extreme conditions is critical.

High-Speed Motion Solutions for Biomechanical Applications

Biomechanics research focuses on understanding how biological structures move, respond to forces, and adapt under various conditions. Whether studying joint articulation, muscle activation, or impact injuries, analyzing rapid, multi-directional motion requires advanced imaging systems with high frame rates, precise spatial resolution, and robust tracking algorithms capable of capturing complex motions in real time.

Fastec Imaging’s high-speed cameras, combined with Image Systems’ motion analysis solutions—including 2D/3D tracking, 2D/3D Digital Image Correlation, and 6 Degrees of Freedom (6DoF) analysis—provide a complete platform for measuring displacement, strain, velocity, and orientation during dynamic movements. This integrated solution enables researchers to capture subtle deformations and rotational behavior with sub-pixel accuracy, offering comprehensive insights into biomechanical function.

Key Applications:

- Joint Articulation & Movement Analysis:

Use 2D tracking to measure joint angles and limb movement in planar motions, while applying 3D DIC to capture out-of-plane deformations, providing a complete view of joint dynamics and load distribution during motion.

- Gait, Posture & Balance Assessment:

Monitor complex movements such as walking, running, or standing using 6DoF analysis, which tracks both linear displacement and rotational orientation in real time, enabling accurate assessment of stability, muscle coordination, and motion symmetry.

- Impact and Injury Mechanics:

Analyze high-speed impacts by measuring strain and displacement at critical tissues with 3D tracking, providing insights into how sudden forces affect bones, ligaments, and muscles. Use 6DoF measurements to understand rotational forces contributing to injury mechanisms.

- Muscle Dynamics & Soft Tissue Behavior:

Study deformation patterns using 3D DIC to map strain fields across muscles and soft tissues under load, while velocity measurements from high-speed tracking help assess contraction efficiency and mechanical response.

- Sports Performance & Technique Optimization:

Leverage 2D and 3D tracking to refine athletes’ movements by capturing high-speed limb trajectories and joint rotations, improving technique while minimizing injury risks.

- Wearable Tech and Ergonomics:

Integrate motion analysis into wearable devices or assistive tools by using 6DoF tracking to observe how orientation and displacement change during movement, helping engineers design ergonomically optimized solutions.

By combining Fastec Imaging’s high-speed data capture with Image Systems’ state-of-the-art algorithms, researchers and clinicians can explore biomechanical processes with unmatched accuracy and depth. This integrated solution is widely adopted in medical diagnostics, sports science, rehabilitation, and ergonomics to improve understanding, prevent injuries, and enhance human performance.

Measurement Solutions for Fluid Flows and Combustion Study

Understanding the complex behaviors of fluids and combustion processes is critical in fields such as propulsion, chemical engineering, energy research, and environmental studies. These phenomena involve rapid changes in flow patterns, turbulence, mixing, and reaction dynamics that occur in milliseconds or less, requiring advanced imaging and motion analysis tools capable of capturing transient events with precision.

High-speed imaging combined with multi-dimensional motion tracking provides researchers with the tools to visualize, measure, and interpret these fast-paced processes. With capabilities such as 2D tracking, 3D analysis, and 6 Degrees of Freedom (6DoF) motion measurement, this technology enables detailed observation of fluid behavior, turbulence structures, flame front propagation, and interface interactions under varying conditions.

Key Applications:

- Flow Visualization:

Observe laminar, turbulent, and transitional flow patterns in wind tunnels or pipe systems, using high-speed capture to analyze velocity fields, vortices, and recirculation zones with sub-millisecond accuracy.

- Spray and Atomization Studies:

Measure droplet formation, breakup, and dispersion in fuel sprays or aerosol flows, using 2D tracking and high-resolution imaging to refine injection strategies and improve mixing efficiency.

- Combustion Dynamics:

Track flame fronts, reaction zones, and heat release patterns during ignition and combustion events, applying 3D analysis to quantify flame propagation and instability in controlled experiments.

- Mixing and Interface Interaction:

Study how different fluid layers interact, merge, or separate by capturing interface deformation and mixing behavior, providing insights into efficiency improvements in reactors or microfluidic mixers.

- Thermal Effects and Expansion:

Analyze how temperature gradients influence fluid motion and combustion characteristics by correlating strain, velocity, and displacement fields across heated zones.

These advanced imaging and motion tracking solutions empower researchers to gain a deeper understanding of fluid and combustion dynamics, helping optimize designs, improve efficiency, and enhance safety in applications ranging from propulsion systems to chemical processing.

Ballistics and Impact Testing Applications

Ballistics and impact testing involve studying how materials, structures, and protective systems respond to high-speed forces such as shockwaves, projectiles, and explosive impacts. These events occur within microseconds to milliseconds and require imaging and motion analysis tools capable of capturing rapid movements, deformation, and force propagation with high accuracy and minimal distortion.

By combining high-speed imaging with advanced motion tracking—including 2D displacement tracking, 3D analysis, and 6 Degrees of Freedom (6DoF) measurement—researchers and engineers can gain detailed insights into impact dynamics, projectile behavior, and material failure modes. These solutions are essential for optimizing safety systems, designing ballistic-resistant materials, and validating computational models used in defense and aerospace applications.

Key Applications:

- Projectile Behaviour Analysis:

Track trajectory, velocity, and orientation using 6DoF measurement, providing accurate data on how projectiles travel through air or impact surfaces under varied conditions.

- Shockwave Propagation:

Capture pressure waves and deformation patterns with high-speed imaging, allowing researchers to understand how shockwaves interact with structures and protective layers during high-energy events.

- Material Response & Fragmentation:

Use 3D tracking to measure crack initiation, spall formation, and fragmentation dynamics in armor, composites, or metallic structures, helping improve material design and resilience.

- Protective Equipment Testing:

Analyze how helmets, body armor, or blast shields deform or dissipate energy under impact forces by observing displacement patterns and stress distribution using 2D and 3D motion analysis.

- High-Speed Impact Events:

Study crash dynamics, debris interaction, and surface failure by recording high-speed impacts at thousands of frames per second, capturing transient behaviours that are impossible to observe otherwise.

- Velocity and Force Measurements:

Measure acceleration, deceleration, and force distribution across materials and structures, helping engineers fine-tune designs for optimal performance under real-world conditions.

- Validation of Computational Models:

Provide high-resolution motion data that correlates with simulation predictions, allowing for refinement of computational methods and better material and structural modelling.

This integrated imaging and motion tracking solution empowers researchers to make data-driven decisions in the development of safer, more efficient materials and protective systems. By understanding how impacts affect structures in real time, teams can enhance performance, reduce risk, and drive innovation in defense, aerospace, automotive, and safety engineering.

Advanced Motion Analysis for Automotive Applications

Automotive safety and performance testing demand accurate observation of vehicle behavior during dynamic events such as crashes, sudden maneuvers, and structural stress tests. High-speed imaging combined with advanced motion analysis enables engineers and researchers to study how vehicles, safety systems, and components respond in real-world conditions, providing data essential for improving designs, validating models, and ensuring compliance with stringent safety standards.

By leveraging high-speed capture along with 2D tracking, 3D displacement mapping, and 6 Degrees of Freedom (6DoF) measurement, researchers gain a complete picture of motion dynamics—whether it’s tracking the rapid rotation of a dummy’s head, mapping deformation patterns, or comparing physical test results with digital models.

Key Applications:

- Crash Scenario and Dummy Head Rotation Analysis:

Measure how occupants and crash test dummies react under impact by tracking 6DoF motion, including rotational angles like pitch, yaw, and roll. This data helps engineers evaluate injury mechanisms and optimize restraint systems.

- Vehicle Dynamics and Structural Response:

Use 2D and 3D tracking to monitor suspension movement, body deformation, and chassis behavior during acceleration, braking, or crash events, ensuring designs meet stability and safety criteria.

- Component Performance Monitoring:

Observe the deployment and interaction of safety equipment—such as airbags, seatbelts, and energy-absorbing structures—through precise displacement and velocity measurements captured at high frame rates.

- Simulation Validation and Error Analysis:

Compare tracked motion data from physical tests with virtual crash simulations, using strain maps, displacement fields, and trajectory profiles to calibrate models and improve their accuracy.

- Compliance and Regulatory Testing:

Support safety certifications by providing validated motion profiles, including head rotation, component interaction, and force distribution during standardized crash events.

With the combination of high-speed capture and advanced motion analysis, engineers can study intricate behaviors—from dummy head rotations to component failure mechanisms—with unparalleled clarity. This enables the development of safer vehicles, more efficient systems, and designs that meet both regulatory and real-world demands.

Motion Analysis for Research and Experimental Studies

Motion analysis software plays a critical role in supporting academic and industrial research by enabling the precise measurement of movement, interactions, and dynamic responses under diverse test conditions. Through high-speed imaging and advanced tracking algorithms—including 2D motion capture, 3D displacement mapping, and 6 Degrees of Freedom (6DoF) analysis—researchers gain the tools needed to explore complex phenomena, validate hypotheses, and push the boundaries of innovation.

By integrating real-time tracking, sub-pixel accuracy, and adaptive filtering, motion analysis software allows for the observation of intricate motion patterns across multiple scales. Whether investigating fluid turbulence, structural vibrations, or mechanical oscillations, researchers can capture velocity profiles, strain fields, rotational behaviors, and acceleration dynamics with exceptional precision.

Key Applications:

- Fluid Turbulence and Flow Dynamics:

Visualize chaotic flows, eddies, and pressure variations by tracking fluid motion in both 2D and 3D, helping improve designs in energy systems and chemical processing.

- Structural Vibrations and Deformation:

Map surface strain, displacement, and resonance behaviors across structures under load, leveraging high-speed capture and 3D DIC for detailed modal analysis.

- Mechanical Oscillations and Motion Profiles:

Analyze rotating machinery, linkages, and assemblies by capturing motion trajectories with 6DoF analysis, providing insights into stress patterns and fatigue behavior.

- Hypothesis Validation and Experimental Correlation:

Use accurate motion tracking to confirm theoretical models, compare with simulations, and identify discrepancies through detailed measurement of displacement, velocity, and rotational motion.

- Noise, Vibration, and Harshness (NVH) Studies:

Measure oscillations and vibrational characteristics to refine designs, reduce noise, and enhance system reliability.

- Cross-Disciplinary Innovation:

Apply motion analysis in biomedical research, robotics, material science, and aerospace engineering to better understand complex interactions in real-world scenarios.

With motion analysis software, researchers can confidently measure, interpret, and present motion phenomena across a wide range of disciplines. The combination of high-speed imaging and advanced tracking algorithms empowers teams to design better systems, optimize performance, and accelerate discovery.

Digital Image Correlation for Structural Analysis

Digital Image Correlation (DIC) is a powerful non-contact optical measurement technique that enables precise analysis of surface deformation, strain distribution, and displacement in structural components. By tracking patterns or textures across an object’s surface during loading, DIC provides engineers and researchers with accurate, high-resolution data on how structures behave under stress, vibration, or environmental conditions.

With both 2D and 3D measurement capabilities, DIC is widely used in structural analysis to understand how materials and assemblies respond to mechanical loads, fatigue cycles, thermal expansion, or dynamic forces. Its markerless tracking, sub-pixel accuracy, and ability to map strain fields over complex geometries make it an indispensable tool for validating designs, improving durability, and ensuring safety.

Key Applications:

- Strain and Displacement Mapping:

Capture full-field strain distributions and surface displacements in structural elements under static or dynamic loading, enabling detailed analysis of stress concentration zones and potential failure points.

- Load Testing and Fatigue Analysis:

Study how repeated or fluctuating forces affect structures over time by monitoring deformation patterns and identifying crack initiation or stress accumulation.

- Vibration and Modal Analysis:

Map oscillations and dynamic response behavior in beams, plates, and mechanical assemblies, supporting fatigue life estimation and structural health monitoring.

- Thermal Effects and Expansion:

Measure deformation and strain due to thermal loads or environmental factors, providing insights into material behavior in extreme conditions.

- Composite and Advanced Materials Testing:

Analyze how modern materials such as composites, polymers, or lightweight alloys deform under stress, helping to optimize designs for aerospace, automotive, and civil infrastructure.

- Validation of Numerical Simulations:

Compare DIC measurements with Finite Element Analysis (FEA) models to refine simulation accuracy and ensure real-world applicability of theoretical designs.

By offering full-field visualization of strain and displacement without the need for physical markers, DIC provides unparalleled insights into how structures deform and interact under real-world conditions. It is a preferred method for engineers and researchers seeking to enhance material performance, predict failure modes, and validate designs in aerospace, automotive, civil engineering, and energy applications.

All brand names, logos, and trademarks belong to their respective owners and are used for identification purposes only.

Copyright © 2025 orbidot.com - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.